Time: 2021-04-22Views: 136

In recent years, the typical processes for manufacturing double-faced metallized printed boards are the SMOBC method and the pattern plating method. In some specific occasions, the process wire method is also used.

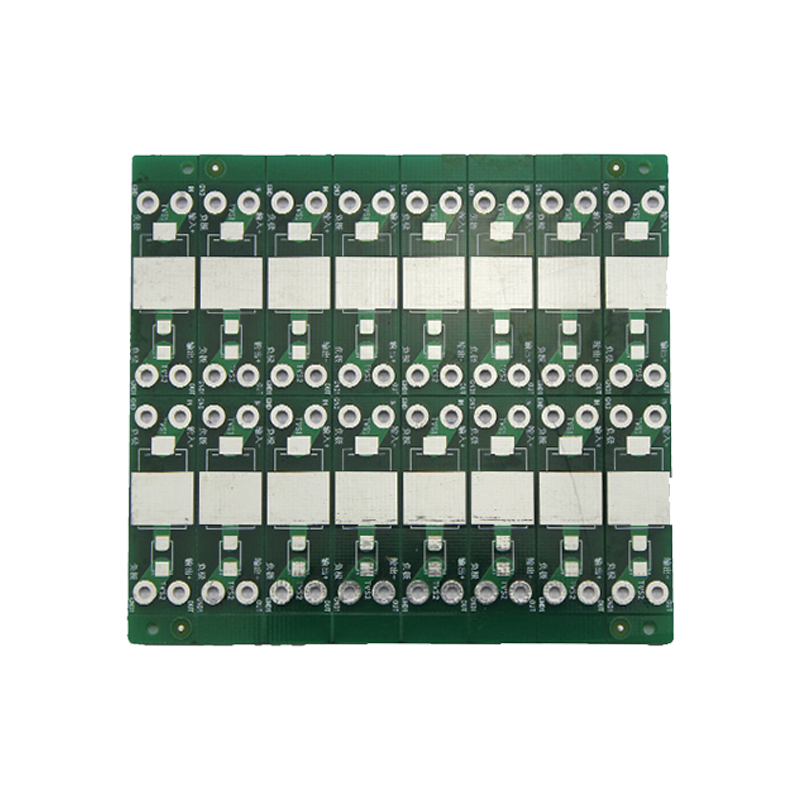

1. Graphic electroplating process

Foil-clad board → blanking → punching benchmark holes → CNC drilling → inspection → deburring → electroless thin copper plating → thin copper electroplating → inspection → brushing → filming (or screen printing) → exposure and development (or curing) → inspection Repairing the board → pattern plating (Cu + Sn/Pb) → removing the film → etching → inspecting and repairing the board → nickel plating and gold plating on the plug → hot melt cleaning → electrical continuity detection --> cleaning treatment → screen printing solder mask pattern → curing → screen printing mark Symbol → curing → shape processing → cleaning and drying → inspection → packaging → finished product.

In the process, the two processes of "electroless thin copper plating → thin copper electroplating" can be replaced by a single process of "electroless thick copper plating", and both have their own advantages and disadvantages. Pattern electroplating---etching method to make double-faced metallized plates is a typical process in the 1960s and 1970s. In the mid-1980s, the bare copper-clad solder mask process (SMOBC) gradually developed, and it has become the mainstream process especially in precision double-sided panel manufacturing.